2013 Pre-Planting Guide

Soon you will be fueling up your tractors, dumping bags of seed and working long hours to get your crop in the ground. Why not take a few minutes and make those stressful days run a little smoother by verifying your Ag Leader investments are in operating order prior to hitting the fields?

Your first step will begin with powering on your display to manage data, update firmware and to create a backup. Be sure the Grower, Farm, and Field information is current; add your varieties for the upcoming year into your product list, and delete any unused data. We do recommend verifying the harvest data from 2012 has been successfully imported into your software program as well. Finally, load your planting configuration to the run screen to verify all modules located on the planter are communicating with the display.

Current firmware for your display can be found here and should be updated prior to the start of the season.

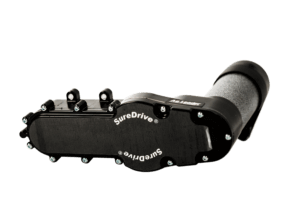

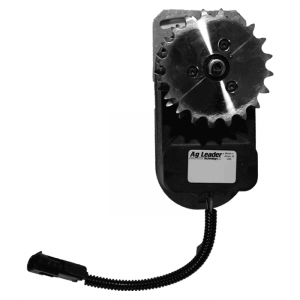

Once your display is ready you will need to move to the components located on the planter. Each of the links below will give you a step by step guide to ensure your clutches, seed tube monitoring, population monitoring and hydraulic drives are working as they should. Don’t forget to check out the Seed Command Pre-Season Checklist for more helpful steps!

Seed Command Pre-Season Checklist

Clutch Control Module Quick Reference Sheet

Seed Tube Monitoring Module Quick Reference Sheet

Planter Population Monitoring for Kinze PMM

Hydraulic Seed Control Quick Reference Sheet

With many of our customers running the new Hydraulic Down Force system this spring; we recommend looking over your planter’s physical setup. This includes all of the row unit hardware such as gauge wheels, seed disk openers and height adjustment levers. Check over cabling and hydraulic hose routing for pinch points or problematic areas. Other important components to check include toolbar height and your toolbar level.

Toolbar Height- From the bottom of the toolbar to the ground should be around 20 inches. We recommend verify this distance with your planter manufacturer. This measurement should be taken in multiple areas across the planter in level field conditions. Ensuring proper toolbar height will provide your actuators’ full range of motion while moving across the field.

Toolbar Level-Check for a level planter toolbar. An unlevel bar will cause weight to be improperly distributed throughout the planter. Top and bottom row unit linkage bolts should be flush with each other as well. Bushings may also need to be replaced on row units if too much free play is found while lifting on the back of the row unit.

To verify actuator and hydraulic circuit operation you will need to:

Lower Planter

Enter Manual Ground Speed

Engage Hydraulic Remote

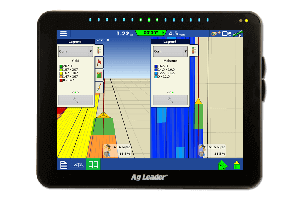

Once the above steps are completed you will need to select the Device icon in the upper right corner of your Ag Leader® Integra display and then select Down Force Module. Once highlighted; press Diagnostics. You will then see a page like this:

On this page you will be able to detect your sensor status as enabled or disabled as well as current sensor readings for your channels. Hydraulic pressure in PSI is also shown. This diagnostic page is an excellent way to determine that all sensors are reading and reporting back to your display.

For any questions you may have please contact support@agleader.com or call 515-232-5363.

Current Support Hours:

Monday-Friday: 7am to 8pm CDT

Saturday: 8am-4pm

Sunday: 12pm-4pm

Tech Support would like to wish you all a safe and successful planting season!