GROWING CONFIDENCE: On-farm field trials improve crop potential

Growing sugar beets in the Red River Valley is an exercise in precision. Hitting the optimal planting depth is of utmost importance to fulfilling the crop’s potentially high — and lucrative — yield potential.

“Getting your stand established is huge for sugar beets,” said Jeff Bjorge, farmer and president of Cutting Edge Ag, an Ag Leader dealer in Buxton, North Dakota. “Any incremental increase in stand and uniformity means many dollars per acre.”

Depending on where you are in the area, that may be easier said than done. The right equipment — namely the planter — helps hit the right planting depth. However, moisture variability and a range of soil conditions make it a challenge, especially when planting time frames are tight. Consistently planting at the optimal depth poses a major challenge to many sugar beet producers who work in highly variable field conditions.

Cutting Edge Ag is located near the geographic center of the Red River Valley, where soil conditions can range from consistent and smooth in the valley itself to hilly and variable around the borders. Farmers in the area employ no-till management on many of the latter acres to maintain soil structures and manage moisture. The region’s diverse growing conditions and need for precision agriculture makes it perfect for Ag Leader to learn on-farm about the importance of downforce during planting season.

Targeting a downforce solution

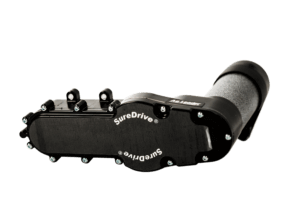

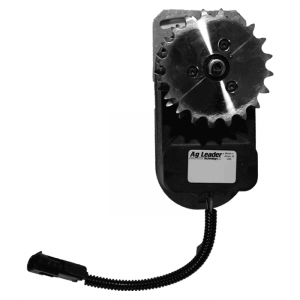

Bjorge has known for some time about the importance of planter downforce in planting sugar beets at the optimal 1-inch depth, so when the opportunity arose to conduct on-farm trials for hydraulic downforce and Ag Leader SureForce® systems, he took it. For him, it was a way to zero in on immediate planting issues and create long-term solutions for both his and his customers’ farms.

“The downforce is a newer thing, especially for the crops we grow here. It’s not 100 percent proven in our neck of the woods, and I want to be involved in showing that it’s actually making a difference in this area,” said Bjorge, who is conducting SureForce on-farm planting trials this summer. “Downforce is important to our ability to hit that 1-inch seeding depth everywhere. SureForce allows you to adjust to your target force on the go. We think it will be perfect going forward because it will allow us to apply as much downforce as we need to get those seeds exactly at the right depth and maximize their value.”

Improving sugar beet seeding is the main reason Biorge and other area farmers are working with Ag Leader Precision Technology Agronomist Barry Anderson. Establishing on-farm planting trials to gauge the efficacy of hydraulic downforce, as well as the SureForce system, will help Bjorge and others in his area create a new benchmark for planting consistency.

“In many areas, corn is usually king. In Jeff’s area, growers use a sugar beet planter to plant corn, rather than the other way around. That’s how important the crop is,” Anderson said. “As we move across different geographies, we always want to come up with specific objectives in our trials. In the Red River Valley, we want to focus on how to improve consistency in seeding sugar beets and other crops.”

Part of a broader effort

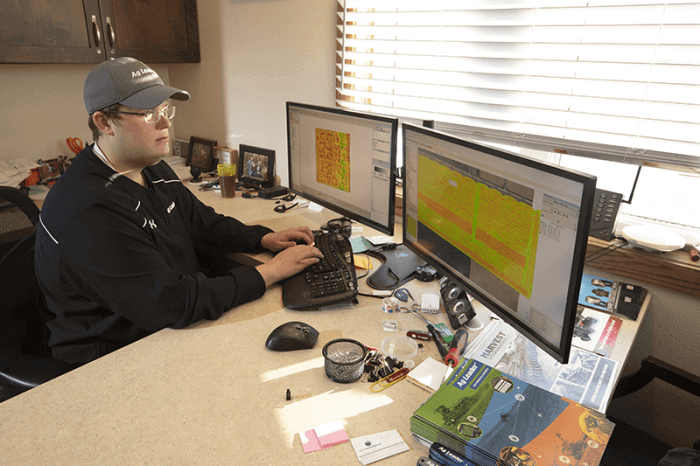

Ag Leader’s agronomy team takes a unique approach to research by seeking information from three sources: in-house, third-party universities, and on-farm trials conducted alongside dealers and grower cooperators. The on-farm component, or Ag Leader “Tech Trials,” are conducted on farms across different geographies, crops and soil types around the U.S.

“The goal is to give growers unbiased opinions about how different uses and applications of technology can contribute to farms in different environments,” Anderson said.

Ag Leader agronomists cast a wide net with on-farm trials — like what’s going on in the Red River Valley — because it plays a huge role in showing the value of Ag Leader technology and tools and how they can contribute to the bottom line of farmers.

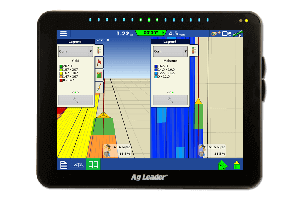

“We have to really just take into consideration the factors that we can document — in this case, factors like downforce, soil type and elevation. So we look at the variables we can control and collect data on emergence and stand counts so we can answer questions later on. We construct trials and replicate them to take into consideration changes we’re going to see,” Anderson said. “By doing that, we’re hoping we can collect real-time, real-farm data that can clearly answer our objective. We ultimately want to answer the questions our customers will be asking when considering adding more of our products.”

In Bjorge’s case, the objective was to confirm a technology and its application that could plant at a steady depth for sugar beet farmers in his area, thereby maximizing early yield potential with consistent emergence. Past research on downforce has already shown the mettle of the practice, and he’s hopeful research throughout the 2019 growing season will confirm the justification for applying downforce at planting, as well as the efficacy of the SureForce system in accomplishing that goal.

“Planting sugar beets is a very slow, careful process, and everything needs to be perfect. One thing off on your planter can cost you hundreds of dollars per acre. We spend a lot of time and energy on our sugar beets,” Bjorge said. “The biggest thing people want to gain in these trials is controlling the perfect planting depth as we go through the field, so we see more uniform emergence, better downforce control and seed placement. We just have to put the seeds in perfectly. With sugar beets, we usually hope for a 60 percent stand, so we work for anything above that.”

The more insight, the better

Anderson said Ag Leader is always looking for farmers who can help support the advancement of new precision ag tools in the future. And, on-farm trials make up a big part of that effort.

“Putting in these trials sometimes has a bit of a learning curve, but we have to have quality data to have confidence making the recommendations we make,” Anderson said. “The more data we collect, the better off everyone will be.”

Ultimately, results of the trials are most valuable when part of a larger, more geographically broad effort. Anderson said he intends to continue working with farmers who raise their hands to be part of Tech Trials on-farm research around the country, adding to the numerous trial locations that are planned for 2019. He hopes to have a body of knowledge that helps farmers determine which Ag Leader tools will help them accomplish their yield, productivity and efficiency goals.

“Farmers have tough decisions to make about technology adoption. We are providing information based on on-farm trials to give decision makers confidence and let them know where technology can make the biggest impact in their operation.” Anderson said.