How SureForce Performs in Conventional Tillage

Spring is just around the corner and I am sure many of you have already been thinking about planting and may have started work in getting your planter ready to go.

Tillage has been a practice used by many over the years in an effort to solve problems such as seedbed preparation, weed control, burying crop residues and leveling the soil, to mention a few. While tillage operations are performed for various reasons, you still need to evaluate the need for each operation.

As your fields are prepared for planting with conventional tillage, your field can be cloddy, layered with a large amount of crop residue and wet. Outside of these conditions, you still have to deal with the various soil types across your fields.

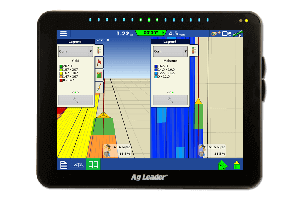

When you put all these variables together, suddenly planting has become more difficult. Uniform emergence is a key for your crop to achieve its highest yield potential. To accomplish this, you need to plant your crop at the correct depth and make optimal seed to soil contact. You may be asking yourself “How can I effectively control each of these variables?” An Ag Leader SureForce system can help achieve this, which may be one of the quickest returns on your investment. Achieving uniform emergence pays dividends in the end with more bushels in the bin. Various land-grant and industry downforce research across the Midwest shows an increase in yield by 6-10%.

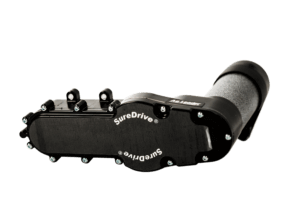

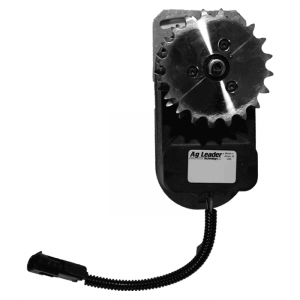

SureForce™ is an active planter row unit system that uses gauge wheel load sensors on each row to sense and respond instantly by either applying or removing force to spatially changing field conditions. It automatically applies force when gauge wheel load is insufficient or in excess as compared to the target setting.

In closing, focusing on the agronomic principles for getting your crop planted at the correct depth and achieving quality seed to soil contact is an aspect you will not regret. Seeding depth and downforce management are critical for optimizing planter performance.