Hydraulic Down Force: Put Control Back into Your Hands

Research has proven that poor planting depth can lead to poor germination, herbicide injury, and plants that are more susceptible to frost injury. Inconsistent planting depths also lead to a lack in uniform plant emergence and growth affecting your overall crop stand. With the increasing understanding of how important a consistent seed trench is to your crop; Ag Leader Technology™ wanted to put the control of planting depth into your hands by introducing Hydraulic Down Force™.

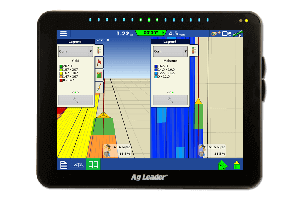

You will now have the ability to control planter down force on-the-go using the Ag Leader® Integra display which will be supported using the John Deere MaxEmerge 2™, MaxEmerge Pro™, MaxEmergeXP™, MaxEmerge XP Pro™, JD XP Pro™ and Kinze™ 3000 series row units for the spring of 2013. This system is designed around a single acting cylinder that adjusts down force instantaneously based on field topography and soil conditions. Control of your planter will be in two channels. Channel one will be for the outer wings of the planter which will be controlled simultaneously to achieve desired down force. The remaining mid- channel of your planter will be controlled independently to accommodate issues of tire compaction and the weight of a bulk fill seed system.

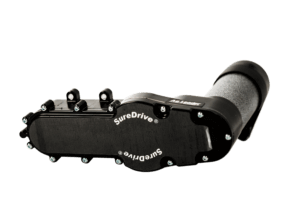

{image1}

There will be three operating modes available to our customers. The first is a monitoring only approach; this will allow you to use an existing setup on your planter such as airbags or springs to simply monitor down force activity with our gauge wheel sensor. Secondly, we have a manual adjustment method; in this mode the grower will be able to manually increase or decrease the applied down force to their desire. Finally, we have the automatic mode; this gives our system complete on- the- fly control to make down force pressure adjustments as our system sees fit.

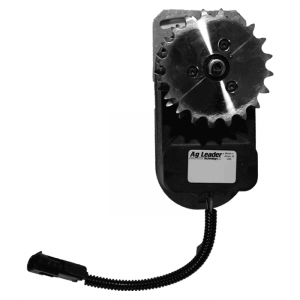

{image2}

Components:

Actuator: Installed on every row unit. Constantly reacts to improve planting depth using hydraulic fluid.

Gauge Wheel Sensor: Senses the weight of the row unit on the gauge wheels. There will be at least two gauge wheel sensors per channel.

Row Module: Module mounted on every row that has a gauge wheel sensor installed on it. This module will transfer information from the gauge wheel sensor to the main control module.

Control Module: Makes down force adjustments across the planter to achieve optimum seed trench depth.

Harness: Connects control module to row modules and implement switches.

Valve Block: PWM valve that is designed to control hydraulic flow to one or two channels adjusting the amount of down force applied. Adjustments are based on information received by the modules.

Hydraulic Hoses: Connects valve block and actuators to the tractors hydraulic system

Nitrogen Accumulator: Acts like a shock in your car to allow for very quick adjustments to the actuator.

Benefits

-

Fastest reacting actuator on the market

- 1 second reaction time compared to a 15-20 seconds on other systems

- 3 GPM of hydraulic fluid is the max our system will ever use

-

Uses up lift springs if less than 0 force is needed

- Optional component

-

Suggested uses are for:

- Planters with seed boxes

- Actuator will fit the John Deere™ air bag brackets

- Proper planting depth no matter the soil conditions or topography

- Two channels of control to achieve optimal down force on entire width of planter

- Limited seed trench compaction

-

System has a nitrogen accumulator

- Works like a shock in your car to allow for very quick relief if the row unit hits a rock or other obstacle in the field

Here is a video explaining how Hydraulic Down Force™ works:

http://www.youtube.com/watch?feature=player_embedded&v=XnRSM5aKQ8s

If you’re in the market for the fastest reacting actuator that will give you the desired seed-to- soil contact you need to promote high yielding crops; contact your local Ag Leader dealer or call into Technical Support at 515-232-5363 for more information.

We look forward to speaking with you soon!