Is your planter ready for #Plant2024?

As the soil in the Midwest begins to warm up, it won’t be long before planters are rolling in the fields. For your planter to perform at its peak, below are key items that should be checked before your implement hits the dirt.

Opening disks

The primary parts of the row unit that create the seed trench. Perfect seed placement requires a perfect trench.

Check for wear. Most seed disks are 15” diameter when new, and they should be replaced if worn at or past 14.5”.

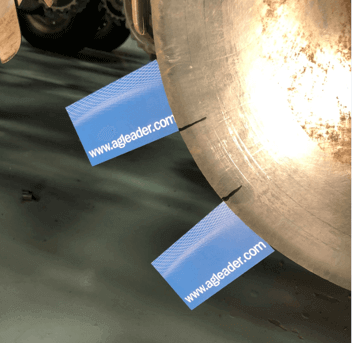

Shim properly with a target of 1.5” to 2” of blade contact area. Using a pair of business cards, slide one in from the top and the other from the bottom. The space between the cards should be about 2”. Most business cards are 2” wide, so you won’t need to use the tape measure here.

Shimming is important because:

-

Too tight generates too much side load on the bearings and will cause premature failure.

-

Too loose and the trench is no longer “V” shaped; instead, it looks more like a “W”. Seeds will not fall to the bottom of the trench, causing inconsistent seed depth.

Always replace the seed tube guard when replacing opening disks. The guard width is important to keep the edges of the opening disks away from the seed tube. A worn guard may lead to damage at the bottom of the seed tube, causing inconsistent seed placement within the trench. The guard also holds the opening disk apart, ensuring the seed can make it to the bottom of the trench. The bottom of the seed trench should have a “U” shape rather than coming to a sharp point.

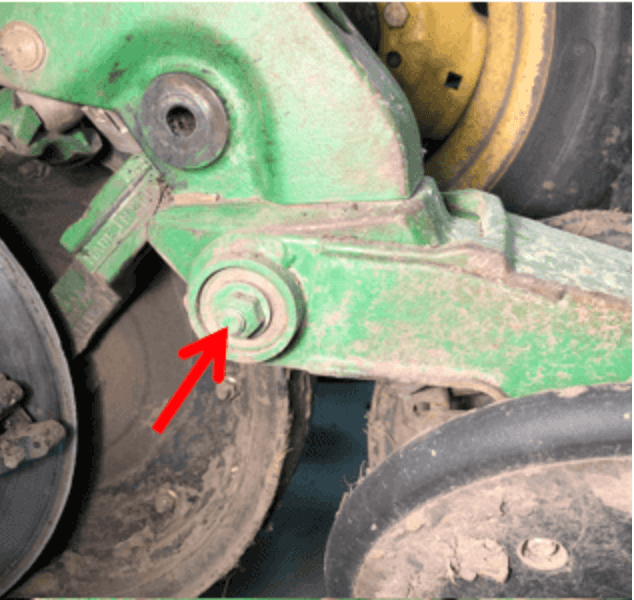

Gauge wheels

Gauge wheels should be adjusted so that when they are pulled away from the opening disks, there is very slight contact.

Proper adjustment is important because:

- Too tight and the gauge wheel will not turn freely. This can cause premature wear to the gauge wheel, or worse yet, it may not turn in softer soils, causing the row unit to plow soil, rather than create a trench.

- Too loose and the gauge wheel will allow dry soil at the surface in between the opening disk and the gauge wheel. The dry soil falls into the trench prior to closing, causing seeds to germinate at varying rates, leading to uneven emergence. In wet conditions, the gap will allow mud to collect inside the gauge wheel, eventually causing it to seize, requiring it to be removed and cleaned.

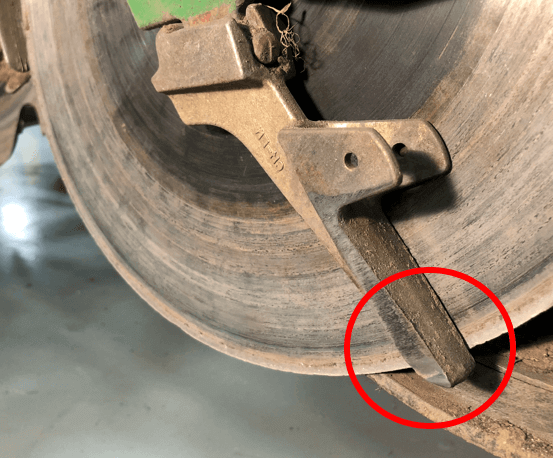

Closing wheels

Closing wheels are potentially the most often overlooked adjustment. Closing wheels should be centered over the trench. When running off the side, the trench is folded one way or the other, allowing air pockets to remain in the trench, leading to uneven emergence.

Simply pull the lowered planter through the farmyard to verify each closing wheel is centered over the trench. If adjustments are required, loosen and adjust until the closing wheels are running level and centered over the trench as pictured in the image on the lower right.