RightSpot® breathes new life into a RoGator 1064 sprayer in Australia

Piawaning district farmers Stephen and Albie Bookham have retrofitted their 20-year-old self-propelled sprayer into a state-of-the-art modern sprayer for a fraction of the cost of a new machine. Their RoGator 1064 sprayer is one of the latest self-propelled sprayers in Australia to be retrofitted with a RightSpot® precision spraying system from Ag Leader.

Stephen and Albie, together with their parents Graham and Marilyn Bookham, conduct a large-scale cropping program across three properties in the Piawaning and Calingiri districts northwest of Wongan Hills, WA.

Over the past six years, the Bookhams have doubled the size of their annual cropping program to about 4,000 ha of canola, wheat, barley, and export hay. This expansion has put pressure on every machine in their fleet, none more than their aging self-propelled sprayer.

“Last January, the spraying system on the RoGator threw in the towel,” Stephen says. “It was finished – nothing worked. The board had completely crashed and the wiring had short circuited. There was no technical support available because it was so old, so we had no choice but to either buy a new sprayer or try to rebuild the old one.”

The Bookhams had just bought a new combine, so they weren’t really in the market for a new sprayer, but Stephen says they were keen on getting something bigger.

“Trying to get over three properties 50 km apart with a 4500 L tank and 30 m boom can be difficult in terms of scheduling,” he says. “We were particularly interested in getting a pulse width modulation system (PWM) because we have lots of undulating country, irregular-shaped paddocks and trees.”

READ MORE: SeedCommand® revitalizes ageing planter

Australian farmer Stephen Bookham says, “We got all the latest spraying technology for a fraction of the cost of a new or used sprayer. And the coverage is perfect whether you’re doing 3 or 30 km/h.”

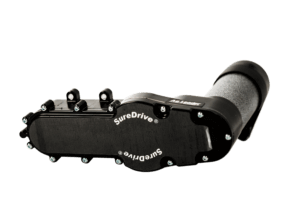

Pulse width modulation (PWM) systems like Ag Leader’s RightSpot allow the Bookhams to move beyond the limitations of a conventional sprayer to ensure products are applied at the right rate and at the right coverage.

The RightSpot Difference

With flow-based spraying systems, you must maintain speed to maintain pressure – and that’s how accidents involving boom tips happen.

“We identified the model we thought we wanted, but we were told we’d be waiting 12 months for delivery, so we started looking at second-hand machines,” Stephen says. “They were asking $300,000 to $400,000, even though these machines had far higher operating hours than our RoGator, and they weren’t anywhere near in the same condition.

A chance conversation with Perth-based precision agriculture dealer Doug Jeans from GPS Agriculture Services provided the solution they were after.

“We were talking to Doug about installing an Ag Leader steering system in our combine and he told us about RightSpot,” Stephen says. “It sounded exactly like what we wanted, so we got a quote. We were quite surprised to find out we could get all the latest spraying technology for a fraction of the cost of a new or even a used sprayer.”

The system was installed over several weeks, with the RoGator ready for action for the sowing season.

“We are really happy with its performance,” Stephen says. “RightSpot is not just about being able to go faster but rather doing a better job at whatever speed you’re traveling. We usually spray at about 27 km/h, but we know we can slow down if we have to without affecting the spray pattern. We’ve checked the spray pattern using blotting paper, and the coverage is perfect whether you’re doing 3 or 30 km/h.”

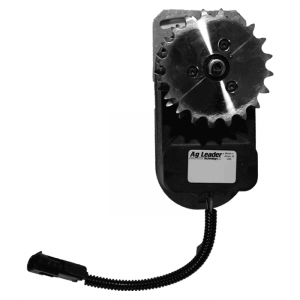

Stephen particularly likes the AutoSwath™ feature, which eliminates over- or under-application. It automatically shuts down each nozzle as the boom passes over previously applied sections, boundaries or headlands, reducing input costs.

The automatic turn compensation function adjusts the application rate of each nozzle to ensure a consistent rate is applied right across the boom during turns.

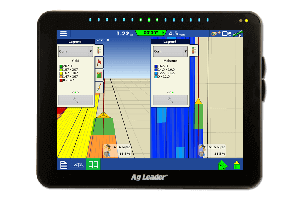

The InCommand® Display: A Superior Screen

He also likes high visibility of the InCommand 1200 display, which provides on-screen monitoring of operating speed, boom pressure, droplet size, nozzle status, and any diagnostic alerts.

“It really is a superior screen,” Stephen says. “It’s extremely easy to use, and there’s zero lag. We’ve got InCommand displays in the Lexion, and we’re looking at putting it on our Challenger MT865 tractor as well, which means all our machines will be connected.

“The guys in the tractor will know exactly where the sprayer has been, which will prevent him from sowing into unsprayed paddocks – or the need to do it all again,” he adds. “In time, we probably will buy a new sprayer, but only because we want a bigger tank and boom – but it will definitely have Ag Leader gear in it.” •