Is there a row guidance solution for InCommand?

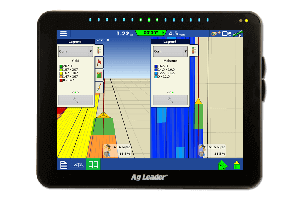

Did you know there is a row feeler guidance solution that works with Ag Leader displays. It’s made possible by ISOBUS Universal Terminal and Reichhardt’s PSR. Reichhardt has developed a line of row guidance sensors and controllers for combines and sprayers that interface with ISOBUS Universal Terminal displays, including Ag Leader.

Jeffrey Bjorge (JB), Cutting Edge Ag in North Dakota, and Chad Brazen (CB), a Reichhardt representative share why this is the perfect pairing.

Q: What benefits have your customers seen using the row feeler solution? What are common reasons for customers adding/wanting row guidance?

JB: The Reichhardt PSR TAC system has been working very well. Our area is on 22-inch rows, predominantly. I use them on our own farm, as well as add them to customer’s units. Even with perfect rows in the flat Red River Valley of North Dakota, we see enough planter draft on RTK that our rows move. PSR Tac row guidance allows us to follow the rows accurately. I like sensor guidance, and we have quite a few systems set up with it. The systems we have are a very robust solution and are allowing customers to use their technology investment to the fullest. I love RTK, but there are a lot of times +/- 1 inch is not close enough. This is where these systems shine.”

A common reason for wanting row guidance can be as simple as wanting to avoid nudging on a corn head/combine. It makes for a stress-free harvest. We also have been adding the system to high-clearance sprayers for following corn in late-season applications. In narrow rows, high speeds, and tall corn, there is no margin for error. This takes the guesswork out of following rows through the field.

CB: The main benefit we’ve seen has been reduced fatigue/stress when operating and allowing the operator to focus more on his surroundings. For sprayers, there also has been times when we’ve seen a reduction in damaged crop in the field.

Typically, the customer is looking for better performance in scenarios where conditions create challenges for GPS-based guidance or even hands-free steering. The most popular uses of our row guidance have been for harvesting corn (downed corn or just for convenience) and following rows of crop with self-propelled sprayers (primarily to reduce crop damage).

With row guidance, the system is able to follow existing crop rather than depending on GPS position of where the crop “should be.” Since our PSR TAC row guidance product can operate independent of GPS position, it focuses on keeping the equipment with the rows, regardless of planting conditions, implement drift, sidehills, GNSS correction, etc. This leads to more consistent performance.

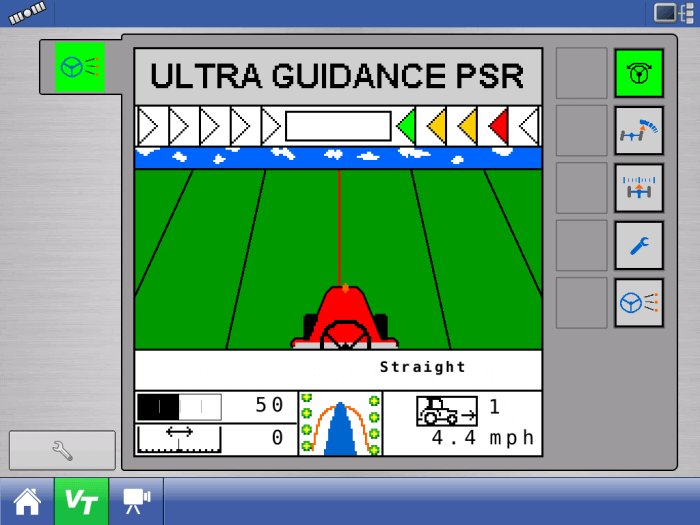

Ag Leader Reichhardt run screen.

Q: How long have Reichhardt systems been out in the field?

CB: We’ve offered PSR TAC row guidance since 2006. There are systems running today over 10 years old that have helped harvest tens of thousands of acres still using the original sensor and paddle.

Q: What do your customers like best about the system?

JB: Everyone likes the fact that once the system is set, there isn’t a lot of “tuning” that has to be done. Whether the system is in a combine with TAC sensors, on a beet lifter tractor running a row finder, or on a steerable hitch reading crop rows with ultrasonic sensors, the system performs and requires very little input from the user. Once a user gets away from nudging, it’s hard to go back.

CB: There are four reasons.

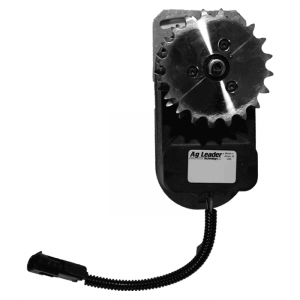

1. Performance. With 10+ years of experience and feedback supporting the PSR TAC sensor, we’ve found several ways to optimize the performance of our system. This includes added functions and improved algorithms for maintaining position in the row when there are gaps in the crop, following curves/pivots and integrating terrain compensation with the system. Also, the TAC sensor itself has two independent inputs providing performance advantages over other sensor solutions when there is an inconsistent stand (Our system is capable of up to 4x inputs using 2x sensors.). The TAC paddle itself “glides” along crop and will naturally follow the base of the plant when harvesting in downed corn situations.

2. Durability. Once the system has been installed and running, there usually is minimal maintenance needed. With our patented flexible “paddle” design, the TAC sensor has proven to be incredibly durable. The operator can also back up the machine without damaging the sensor.

3. Flexibility. The same PSR guidance system can adapt to nearly any make/model machine and support additional guidance modes (as needed). By using the ISO 11783 Virtual Terminal standard, the existing ISOBUS terminal can be used and the same user-interface is provided regardless of display. Also, the same TAC sensor configuration can be used in 20-inch, 22-inch, and 30-inch row spacing. Unique configurations are also available for wider row spacing or specialty crop (i.e. cotton).

4. Simplicity. Since our row guidance product is not GPS-dependent, it does not require management of guidance lines, etc., making the operation and setup easier. There are usually minimal adjustments after the system is setup and running.

Q: Which components are needed to install the complete system?

CB: For a complete system, we require a supported machine that is either factory steer-ready or has steering components added (e.g., valve and angle sensor). Through Reichhardt, we source the entire system. They have full wiring interfaces for most every steer-ready combine as well as many tractors and sprayers. They source hydraulic valves and are compatible with the OnTrac3™ to make their systems fully adaptable to most any machine.

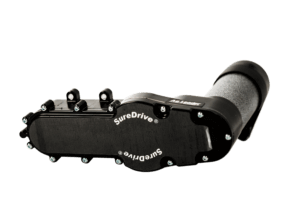

Typically, Reichhardt provides a PSR iBox (controller), TAC sensor/paddle and necessary electrical harnessing to connect to the machine. There is some setup/configuration to the system, which is done via a connected ISOBUS terminal’s UT/VT interface, such as on the Ag Leader® Integra or InCommand display. On sprayers, we use 2x sensors and paddles, which also require unique mounting assemblies.

There you have it. A proven row guidance solution using the industry’s top display, InCommand 1200.