SeedCommand® revitalizes ageing planter

Bonshaw district farmer, Will Ramsay, has rebuilt a 25-year-old row planter into a state-of- the-art precision planter for a fraction of the cost of a new machine. Will and his wife, Kim, grow more than 340 hectares of irrigated cotton, corn, sorghum and barley on Lilyvale, their 800-hectare property located about 40 km southeast of Texas in southern Queensland.

About four years ago, Will was contemplating the purchase of a new precision planter to replace his ageing John Deere MaxEmerge Plus eight-row planter. “We were finding it difficult to get a consistent plant stand,” he says. “Our soil types range from sandy loams to heavy clays and the row units can really bounce around. You might end up with a 2-inch seed depth in the sandy soils and ¾-inch in the clays.”

Will was inspecting planters at FarmFest when a chance encounter with Dalby-based Ag Leader dealer, Ben Tarrant from Darling Downs Precision, provided him with a different solution.

“Ben told me that rebuilding my planter with a SeedCommand® system might be a better option, so I asked for a quote,” he says. “I was pleasantly surprised. It was going to be a lot cheaper than buying a new planter, and it would work in harmony with our existing Ag Leader guidance system. We ended up taking the whole package.”

Darling Downs Precision installed SureSpeed® and SureForce® on Will’s planter last August. Will opted to replace the parallelogram arms, the depth wheel arms, and shanks at the same time.

“All up, we ended up spending about $90,000, which is a lot cheaper than a new, eight-row precision planter,” he says.

READ MORE: RightSpot® breathes new life into RoGator 1065 sprayer in Australia

Australian farmer Will Ramsay found that rebuilding his John Deere MaxEmerge Plus eight-row planter with a SeedCommand system was a lot cheaper than buying a new planter.

“We ended up spending about $90,000, which is a lot cheaper than a new, eight-row precision planter,” Ramsay says.

SeedCommand a major step forward

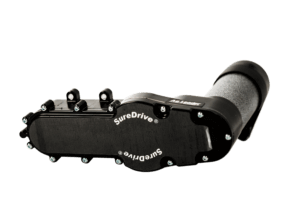

SureSpeed is an integrated three-bushel (105 litre) hopper, singulation and powered delivery system that achieves precise seed placement at any operating speed from 2 to 19 km/h. It places the seed in the furrow at the same speed as the tractor.

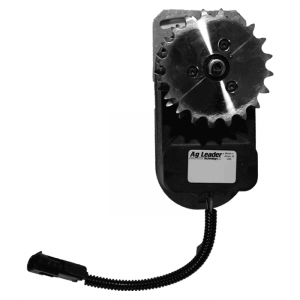

SureForce automatically regulates the downward or upward pressure in each row unit to maintain a consistent planting depth across varying soil types and planting conditions. The dual-acting hydraulic actuators produce up to 295 kg of downforce and up to 115 kg of uplift.

Will has since planted more than 1000 hectare of cotton and corn on Lilyvale and neighboring properties using the refurbished planter.

“SeedCommand is a massive step forward compared to what we had,” Will says. “Our corn yields have increased between 5% and 20%, which sounds extreme but that’s what happened. SureForce has probably been the most important in terms of seed placement, while SureDrive eliminates the skips and doubles you can get with a ground driven metering system.

“We are achieving 98% accuracy with 1% skips and 1% doubles. Before, it was more like 90%. Being able to control each row individually is a big benefit for us when we’re planting under pivots.”

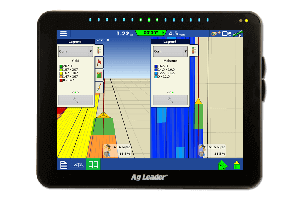

SureSpeed and SureForce are controlled using Ag Leader’s InCommand® 1200 universal display, which also controls the tractor’s SteerCommand® Z2 guidance system. The 30 cm, high-visibility touchscreen can also be used to control Ag Leader’s precision spraying, spreading, and harvesting applications.

Will has used Ag Leader steering guidance systems for more than 15 years with his John Deere 8345R tractor and Case IH Patriot 3330 sprayer both fitted with SteerCommand Z2 guidance systems and InCommand 1200 displays.

“We haven’t really considered any other system because we are so familiar with Ag Leader,” Will says. “Ag Leader works with all the brands, and it does everything on one screen.” •