SureForce Best Practices

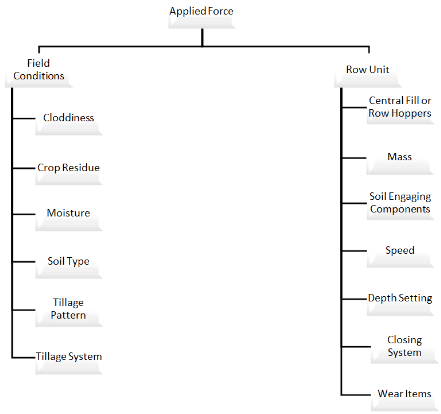

There are two influencers for applied force, the row unit and field conditions. Thinking about downforce in this way can help operators identify potential problems and gain a deeper understanding of information shown on the InCommand® 1200 display as applied force is automatically controlled. Typically the row unit will be unchanging throughout a planting season, whereas field conditions change seasonally and spatially.

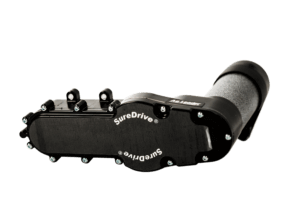

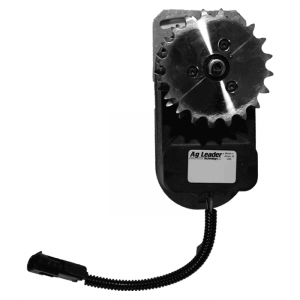

SureForce is an active planter row unit force system that uses Gauge Wheel Load Sensors on each row to sense and respond according to changing planting conditions. Gauge Wheel Load is defined as the force being measured on the gauge wheels at any point during planting. Gauge wheel load is needed to achieve and maintain target depth at all times. SureForce acts to automatically apply force when gauge wheel load is insufficient or in excess as compared to the target setting.

SureForce Operational Principles

In the display, the default setting is Medium and is recommended as a starting point for all planters, field conditions, and crops.

Each SureForce setting has an associated target for gauge wheel load and ground contact. Target gauge wheel load will be overridden by SureForce when ground contact measurements are less than the target. Ground contact is determined by monitoring gauge wheel load over time as the planter travels through the field.

- Minimum – 50 lbs target gauge wheel load

- Light – 75 lbs target gauge wheel load

- Medium – 100 lbs target gauge wheel load

- Heavy – 150 lbs target gauge wheel load

- Maximum – 200 lbs target gauge wheel load

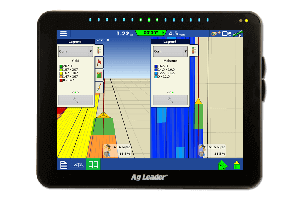

Row-by-row SureForce gauge wheel load maps on InCommand 1200 shows median load values every second. Each row unit’s load is sensed at 200 Hertz. The length of time insufficient gauge wheel load occurs is proportional to the amount of depth loss. Longer time of insufficient gauge wheel load = more depth loss. For this reason, it is discouraged to increase time threshold in the gauge wheel load alarm settings.

After the operator has spent the time to gain an understanding of all forces impacting the row unit during planting, gauge wheel load settings can serve as a valuable tool for fine-tuning the system.

Choosing to operate SureForce in a specific automatic control setting other than default and/or manually based on an arbitrarily determined applied force or gauge wheel load target is not advised.

Best Management Practices

Consult with a trusted agronomic advisor to gain an understanding of the impact of seed depth and sidewall compaction to the crop being planted. Set target depth and begin planting in Medium. The objective is to achieve and maintain target seed depth at all times without inhibiting root development from over compaction of the seed trench.

IMPORTANT: Proper Force is between the extremes of inadequate force resulting in depth loss or excess force resulting in compaction.

Using the applied force maps on InCommand 1200, check for depth loss in areas of the field with the lowest and highest values of applied force. If depth is being routinely lost, consider moving to a higher setting.

Using the applied force maps on InCommand 1200, check for compaction in areas of the field with the lowest and highest values of applied force. If compaction is being routinely observed, consider moving to a lower setting.

When might I expect to use a setting other than the default (Medium)?

Field conditions that may require less gauge wheel load:

Typically it is not one factor but rather a combination of these factors.

- Conventional tillage systems that can create very loose soil

- Sandy soils

- Excess moisture

- Field conditions that may require more gauge wheel load

- Typically it is not one factor but rather a combination of these factors.

- Dense cover crops

- Reduced tillage systems

- Drought conditions

- Cloddy seedbed

Interested in learning more about SureForce? Talk to your local Ag Leader dealer!