SureForce® Breaks Through the Challenges of No-Till

It is no secret that ground conditions and tillage practices present different challenges for growers during planting season. Those who practice no-till with cover crops can have the most difficult environments for planters when it comes to seed placement –– specifically seed depth. Time and again our TechTrials reveal that no matter the farming practices, or ground conditions seed depth makes or breaks yield potential.

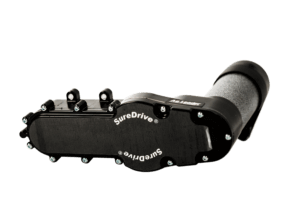

The solution to this challenge: SureForce®. Our hydraulic downforce and uplift system. SureForce will make sure your planter is achieving the proper depth by applying up to 650 lbs of downforce, no matter how difficult planting conditions become.

The Trial: Springs vs SureForce

This trial was conducted in Virginia with a 12–row planter, equipped with gauge wheel load sensors, which allowed us to view how the factory springs perform. The planter was then broken down by rows.

- Rows 1 – 6 = Factory Spring Down Force

- Rows 7 – 12 = SureForce

SureForce Improves the Bottom Line

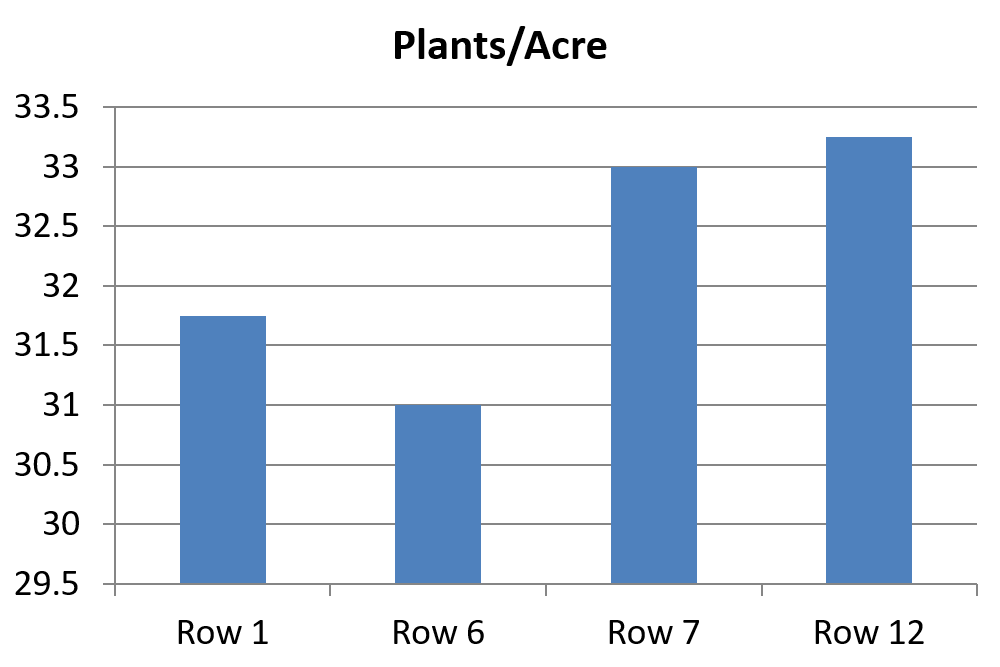

The stand counts of SureForce rows (Graph 1) show an improvement by about 2000 plants per acre compared to the spring rows.

After scouting the field and evaluating the data, the results showed SureForce had more consistent emergence, improvement in final stand, and better developed root structure.

How much does that add to our bottom line?

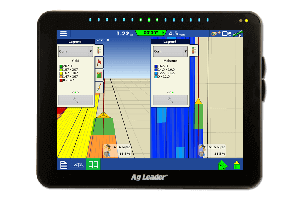

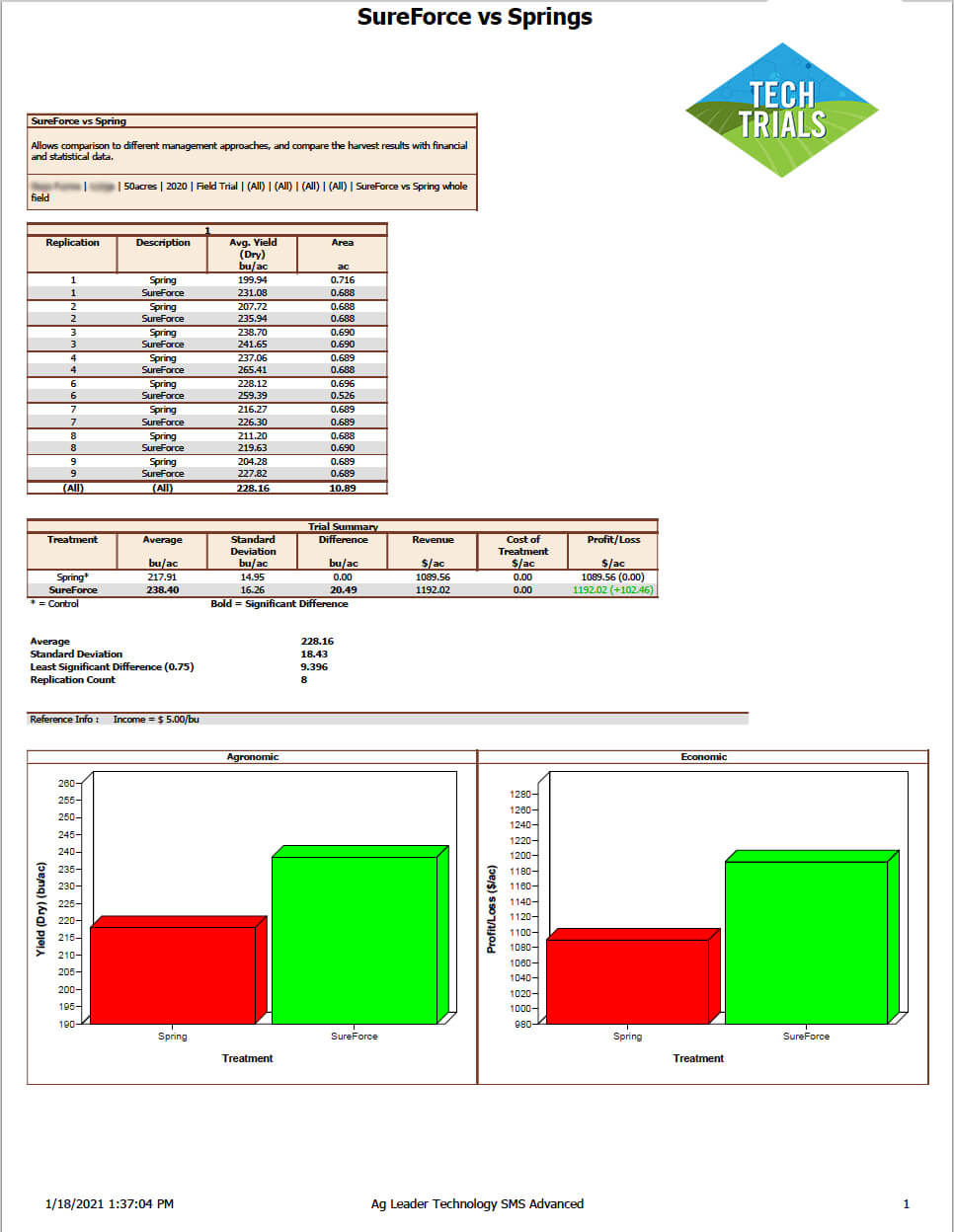

Using the new SMS™ software field trial tool makes it easy to understand your results. Not only does it show the yield difference; it tells us if the results comparing SureForce and spring systems are statistically significant.

(Graph 1)

The analysis report (Figure 1) shows that SureForce was able to generate an extra 20.5 bushels per acre in this field, which generates over $100 per acre in return. Not to mention the stress relief of automatically adjusting SureForce compared to manually set springs or airbags.

(Figure 1)

Viewing Data in AgFiniti

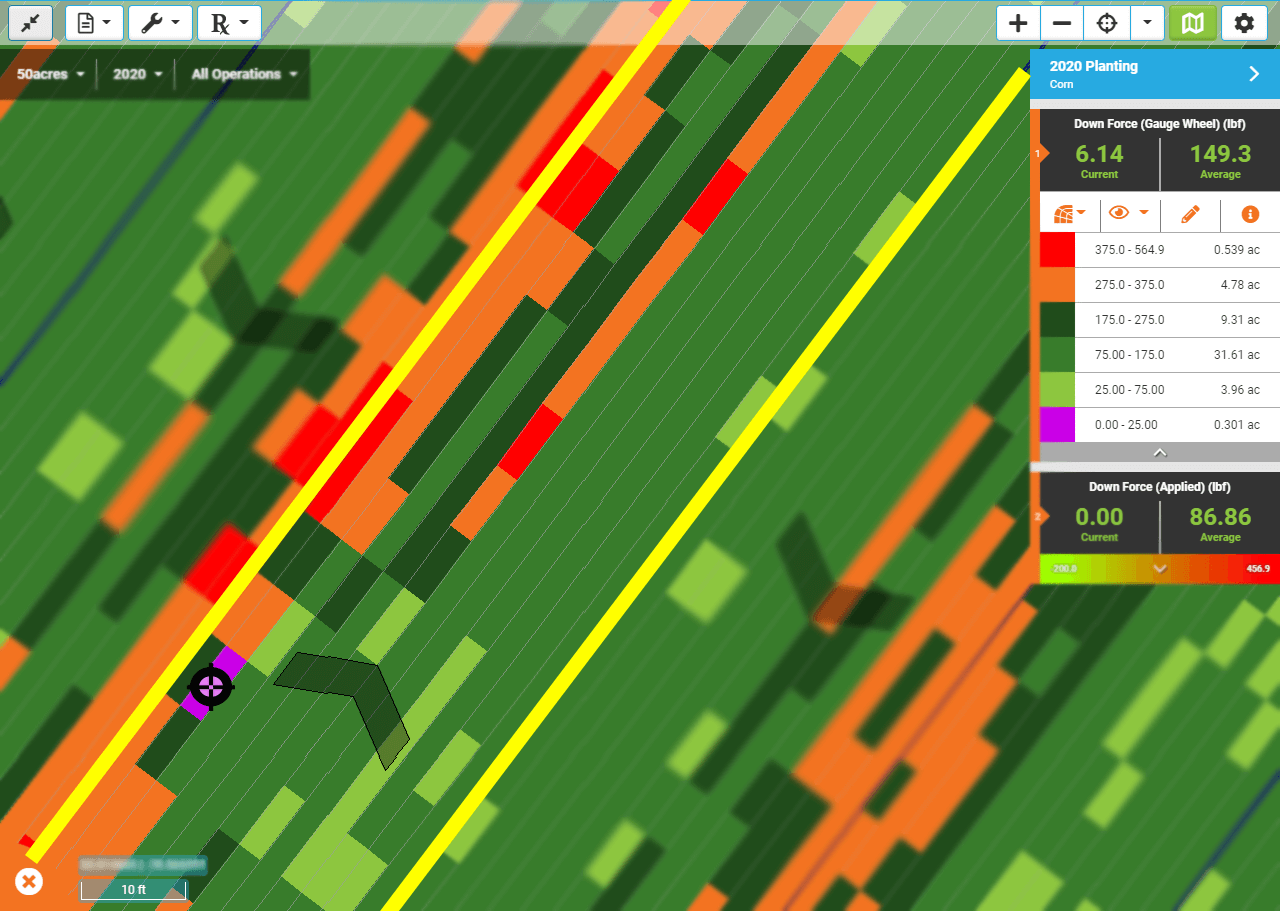

AgFiniti®, allowed us to view the individual row performance, which made it is apparent there were some short comings with the factory equipped springs.

In Figure 2 you can see an abrupt change in gauge wheel load on row two at the target icon. In a matter of 50 feet, the measured load ranged from 6 – 378 lbs. Row two planted some seeds shallow and caused damaging compaction where we would have ideally achieved around 150 lbs of gauge wheel load. Springs simply didn’t do a good job in these difficult no-till conditions.

Notice the improved consistency of gauge wheel load on the right half of the planter compared to the left half. It’s easy to see a difference in performance in the data.

What about in the field?

(Figure 2)

The Field Tells All

Let’s start by looking at what happens in areas where we had little to no gauge wheel load. In Figure 3, you’ll see a seed that was left on top of the ground, which is common with springs in this amount of residue.

What happened to the rest of the field? The next picture (Figure 4) illustrates what happens when too much downforce is applied in areas with light soil or less challenging conditions.

(Figure 3)

(Figure 4)

Notice in Figure 4 the trench is left visible on row 6. This is a sign of a compacted seed trench. The trench was closed well enough for germination to occur, but as the soil dried, the ground cracked, exposing the seed trench and the developing roots.

Figure 5 shows how the roots develop when the seed trench is compacted. The roots are trapped within the trench; limiting access to water and nutrients, and restricting future plant development.

Desirable root development is not impeded by the trench side wall. When digging, it should not be obvious where the trench was created. The ground should be uniform, as it was before the planter pass. Figure 6 is a good example of a robust root system.

(Figure 5)

(Figure 6)

Next, let’s use some quantitative data to evaluate how SureForce performance compares to springs.

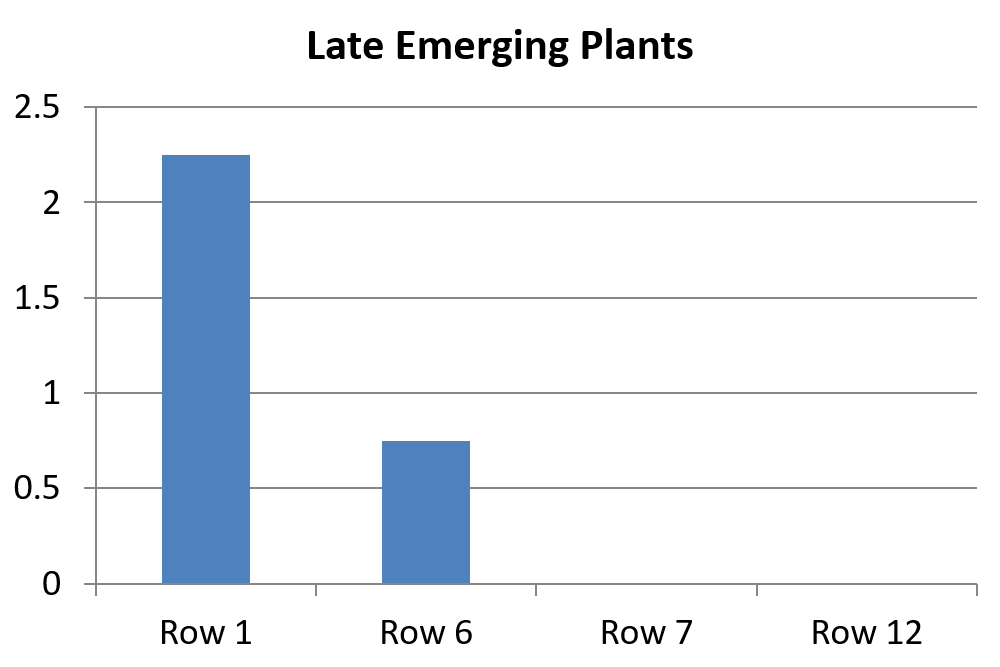

Late emerging plants are caused by planting too shallow, having poor seed to soil contact or both. In these instances, moisture is either not available, or is pulled into the seed slowly delaying emergence. These plants end up functioning like weeds because they never catch up, never put on a harvestable ear, and waste nutrients available to neighboring plants. In this trial (Graph 2) the rows equipped with springs generated about three late emerging plants per 1/1000th of an acre. That is about 10% of the seeds planted by rows 1-6 equipped with springs.

The combined trial data from SMS and AgFiniti and our field visit, makes it clear that SureForce takes the win and provides accurate seed depth placement in tough conditions!

(Graph 2)

Check out stories from past trials for no-till and conventional till fields.

Give your local Ag Leader dealer a ring and find out about what’s working best in your area and what might be right for your farm.