SureForce® Performs Flawlessly in Cover Crops

As an Agronomist for Ag Leader, I have spent the summer traveling across the country evaluating Tech Trial performance and helping growers and dealers better understand planters and planter performance.

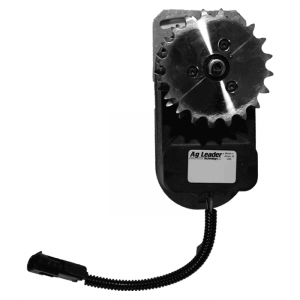

One Indiana grower I visited with explained that SureForce® alerted him of frequent spikes in downforce while the gauge wheel load readings would remain consistent. The grower, Dave, expected that similar applied force readings should generate similar gauge wheel load readings. Why were there some rows that didn’t follow this behavior?

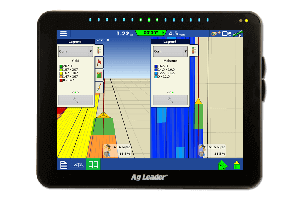

We examined his maps on his iPad using AgFiniti®, and noticed rows two and ten of the 12-row planter were the worst offenders. Gauge wheel sensors on these rows had been replaced, but the problem persisted.

We spent some time investigating the planter, paying close attention to row two. Still, we were unable to find anything that would cause this row to require different amounts of downforce than neighboring rows. We found the adjustments were all correct, and it was clear that this grower prioritized equipment maintenance. Dave took us to the field where the problem was most evident.

According to the map on AgFiniti combined with our live GPS location, we stood at the point where downforce had been applied much higher and it was immediately obvious to us all that there was a simple explanation for the increased force.

THE CAUSE

The rows of corn were planted into a standing rye cover crop. However, at this spot the rows of rye matched perfectly with the rows of corn and were planted directly on top of the rye row. Due to slight differences in row spacing, this overlap would not happen in every row simultaneously. This led the grower to think the system was applying too much force randomly.

THE WIN

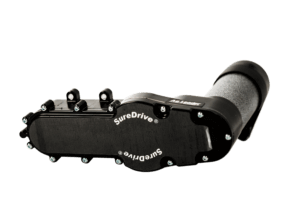

At the beginning of the day, Dave mentioned that he had a hard time seeing the value in his investment in the system. After identifying where corn rows intersected the rye strips, and digging up plants to check seeding depth, we found that everything was consistent at 2″, whether it was directly on top of the rye, or perfectly in between the rye strips. SureForce performed flawlessly. Without this system, the corn planted over top of the rye would have been extremely shallow, and likely would not have grown, let alone yielded a harvestable ear. Dave now believes in the value of Ag Leader’s SureForce.