Tips from Tech Support: End of Year Storage

With field operations nearing completion for the year, it’s time to start thinking about protecting your investment. By taking a few moments to properly store your Ag Leader equipment, you can help ensure continued trouble-free performance of your displays and operating systems.

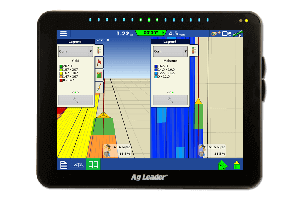

Extreme temperatures take a toll on almost everything that surrounds us, and that includes the high-tech electronic equipment found in our tractors, sprayers, spreaders, trucks and combines. Extreme cold will cause parts to shrink and become brittle, as well as allow condensation to form on parts that are not sealed. It’s always a good idea if you’re not using your Ag Leader display to remove it from the vehicle, put it back in its packaging and store in a climate-controlled environment. This is also a good time to clean the touchscreen on your display. If there is dust or dirt on the screen, first blow it off using non-direct air to remove the dust that could scratch the screen. Then you can use Windex or an electronic cleaner/wipe with a soft, non-abrasive cloth. Do not spray directly on the screen, but rather spray the cloth and then clean the display. When it comes to the equipment there are a few recommendations that can keep your cabling and modules in top shape as well. Many of the chemicals and fertilizers used in today’s farming operations can be very damaging and cause corrosion on your cables and connections. Take extra care when cleaning the equipment to also clean connections and cabling by applying dielectric grease to terminals and contacts. If any of the cables show signs of corrosion, take corrective action now by either providing additional protection from the elements or replacing the cable. While cleaning, also inspect the cables for damage at any pinch points or corners and near moving parts.

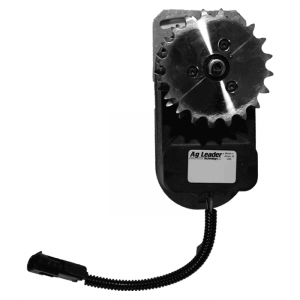

Yield Monitor systems also need some special attention. If you’ve already put your combine away for the year, go back and check the cabling as stated above. In addition, you will want to make sure the Elevator Mount Unit (EMU) on your clean grain elevator is cleaned out. Pull the two retaining pins at the bottom of the EMU to remove the auger. Thoroughly clean all the grain out of the chamber and make sure there is nothing stuck in front of the proximity switch. Lastly, the load cell for the flow sensor is surrounded by a protective potting material that can be easily damaged by small rodents. To prevent this, pull the flow sensor off the top of the elevator and store it in the house, shop or a sealable container. By taking these precautions now, you can help ensure that your equipment will perform properly the next time you use it, and you will also be protecting the investments you have made in your precision agriculture technology.