Which Weighing Device are you using to calibrate?

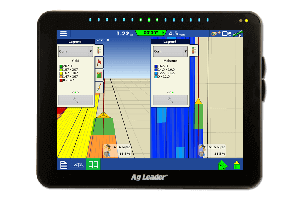

As you may know, InCommand™ displays can now get you quality, actionable yield data in one or two calibration loads.

We’re all familiar with the term garbage in, garbage out, right? Accurate actual weights are particularly important now when calibrating with fewer loads because weighing inaccuracies don’t average out over many loads.

Ag Leader offers a few different methods that are acceptable for capturing calibration load weights. Certified scales are the preferred method, though grain cart scales or weigh wagons may also be used – your choice may be impacted by what is most convenient to you. Each method has their merits and detractors.

Every fall, Ag Leader harvests thousands of acres and continually performs weight calibrations. In this blog, I will go over each of the weighing methods and share some best practices we’ve gleaned from hours and hours in the field.

Certified Scales

Certified scales are always going to be the best option for getting an accurate weight for your calibration load.

We recognize that the time or logistics of doing so is not always the most convenient for all operations to run a grain cart or semi to the elevator.

Certified Scale best practices:

- Calibration load size: 1 full combine grain tank.

- Always start calibration loads with an empty combine and transport device.

- Calibration loads must be transported and tracked separately from other harvested grain.

- Avoid starting a calibration load opening a field or when switching between varieties to ensure consistent grain flow.

Weigh Wagons

Weigh wagons are another way to get weight readings but finding one may be a struggle during the busy fall season. Luckily, the Ag Leader yield monitor can back-calibrate which means you can have first-rate yield data, no matter when in the season you calibrate.

One caution with weigh wagons – despite their name, there can be some error. In private research, Ag Leader has found some manufacturers to state 10% error to be “within spec”. Additionally, some weigh wagons do not have the ability to be calibrated.

Weigh Wagon best practices

- Calibration load size: 3000lbs up to weight wagon max capacity.

- Always start calibration loads with an empty combine and weigh device.

- Use consistent load size for all calibration loads taken.

- Entire calibration load must fit in weigh wagon without overfilling wagon or leaving grain in combine grain tank.

- Unload from combine directly into weight wagon.

- Avoid starting a calibration load opening a field or when switching between varieties to ensure consistent grain flow.

Grain Carts

Grain carts are an easy option for most users. They’re on the farm and being used to transport grain – why not use them to calibrate the yield monitor?

Certainly, they can be handy but there are some cautions to take for the best experience.

First, not all grain carts are created equally as far as weight accuracy readings. The more load cells the better the weight can be accounted for.

Also, we’ve found that single auger carts can have more accuracy than dual auger carts. Dual auger carts are typically longer and feature an auger running along the bottom to channel grain forward to the unloading auger. These carts can be backloaded if proper care is not given, resulting in negative hitch weight.

If your grain cart has 3 load cells or is a dual auger cart, please be sure to use extra caution when capturing calibration loads. You may want to use another weighing device for best results.

Grain cart accuracy can change based on fill level so always calibrate the grain cart for the weight you typically load. For example, if you always fill your grain cart, be sure to calibrate with a full grain cart weight.

Key takeaways

- Calibration loads are best taken across a certified scale

- Grain carts can be 3-5+% off compared to certified scales

- If using a grain cart, follow best practices

Learn more in the InCommand Harvest Feature User Guide!